Britestone is one of the leading manufacturers & suppliers of high-quality Abrasives, Super Finishing and Diamond Honing sticks since 1998. Our Products are manufactured in highly standardized manner, using the finest raw material, our products are available in many sizes, grits and grades & can be customized as per the specifications we offer.

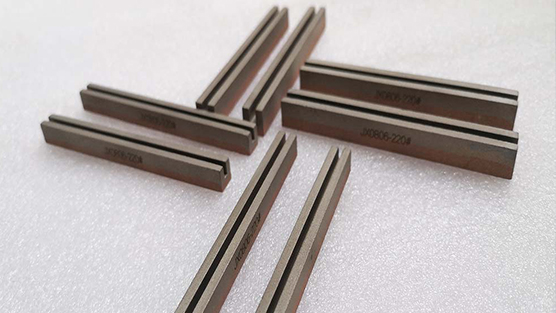

BRITESTONE was established in the year 1998 by HERALD PINTO for manufacturing of wide range of Metal Surface Finishing products. Britestone products include Honing stones, Super finishing Stones and Diamond Sticks. During the last 22 years, the company has established itself with a growing reputation for consistent quality and excellent service in the complete range of products. Against continuous enquiry from our esteemed customers. We had developed Diamond Honing sticks in 2005. By the time we had introduced ourselves in many companies including top OEM’s as Tier-1 suppliers across the country. With our stones, our esteemed clients got better results in their product.

All honing Sticks are verfying and pass throuth all testing and methods before delivering our products.

We are supported by a best technical team who have been delivering quality, accuracy and consistent results.

We have been satisfying the exact requirements and needs of our customers.

We can sale direct to customers in manufacturing cost and best rates with good services in India.

Quality standards we always own the policy of continual improvement to keep pace with Technology.

We are well equipped with well-planned layout & additional space for expansion, SPM’s, testing .

When you define your personal values, you discover what's truly important to you.

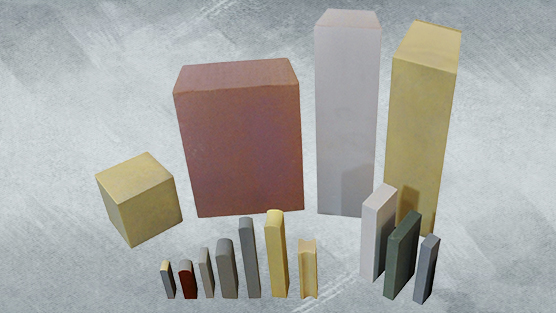

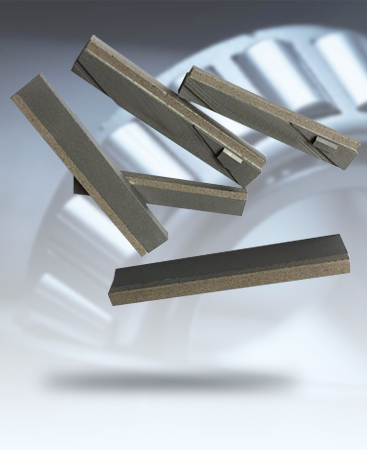

We manufacture the widest range of super finishing stones for a vast number of applications.

Super finishing stones are manufactured from high purity aluminium oxide and silicon carbide in grits

These stones are manufactured in vitrified bond, resin bond, rubber bond as well as flexible PVA bond and are recommended based on the application.

The required finish is achieved by pressing a fine-grained superfinishing stone against the revolving component